Thermal Reflective Insulation - Ideal for the DIY'er.

Xcel Insulation are the distributor of state-of-the-art thermal reflective insulation solutions. Continually introducing new products to our range, we are setting the benchmark for exceptional thermal and acoustic insulation solutions.

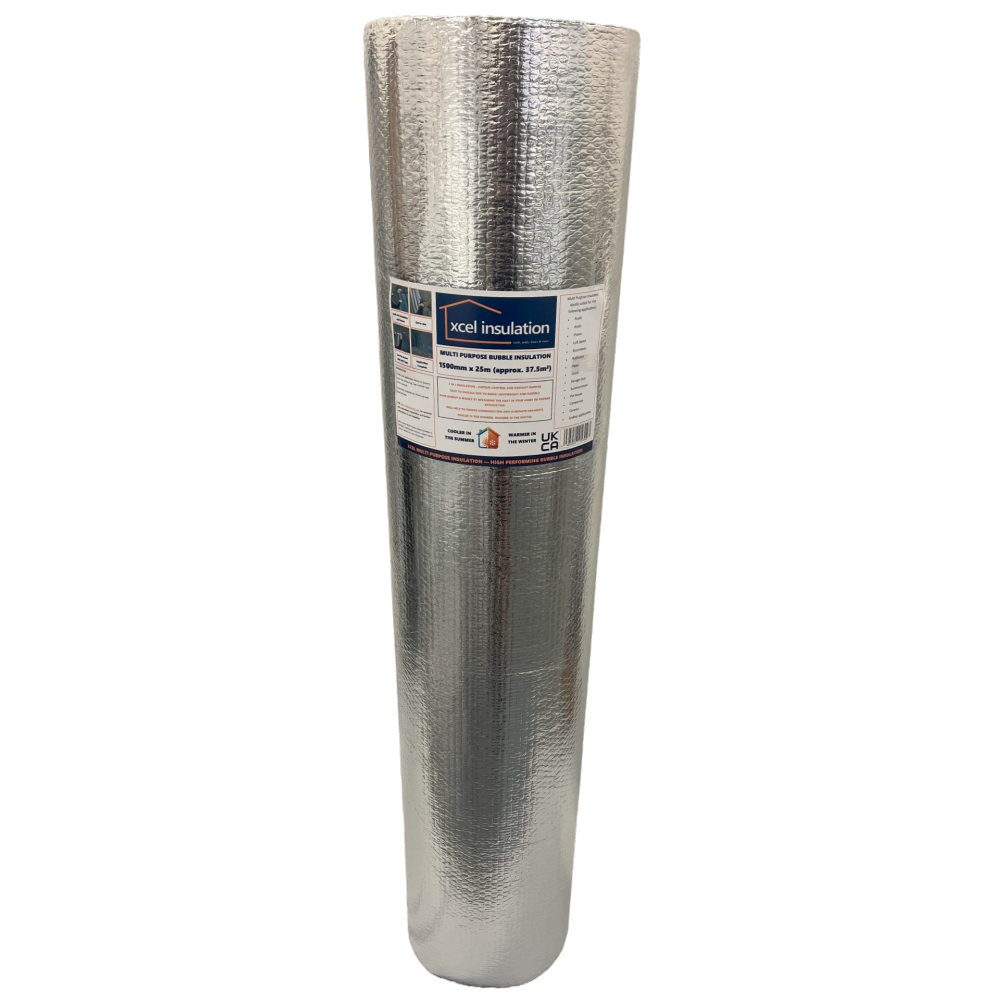

The thermal reflective insulation is thin, flexible and easy to install in almost any household application.

The aluminium outer layers have a reflectivity of up to 97%, is installed with ease, no special tools required, has zero fibres removing the requirement of PPE and discomfort compared to other insulation. Easy to handle and simple to cut to size. And thinner than all other types of insulation products, yet giving the same thermal results.

Products

Please view our products. Click each for more information.

Insulation solutions for your application

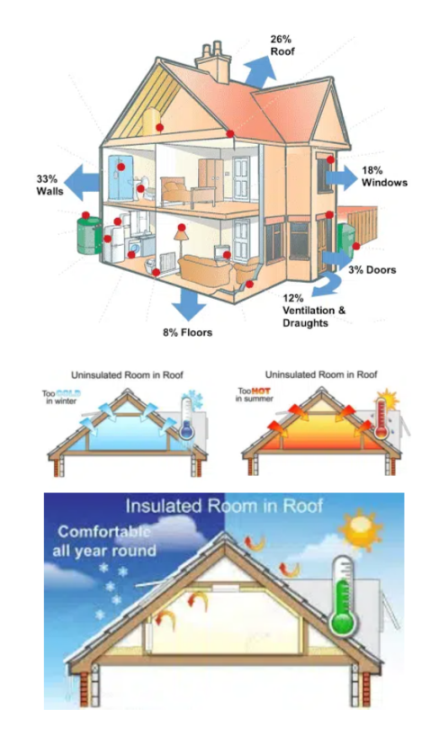

Our thermal reflective insulation products are ideal in almost any household area, significantly reducing energy consumption, translating into energy cost savings.

Our insulation is thin, flexible and easy to install, ideal for the DIY'er.

Where can I install Xcel Insulation?

- Roofs - Walls - Floors

- Loft - Attic - Basement

- Shed - Garage - Summerhouse

- Pet - Hutch, Kennel etc

- Vehicles - Motorhomes, conversions, boats, trucks

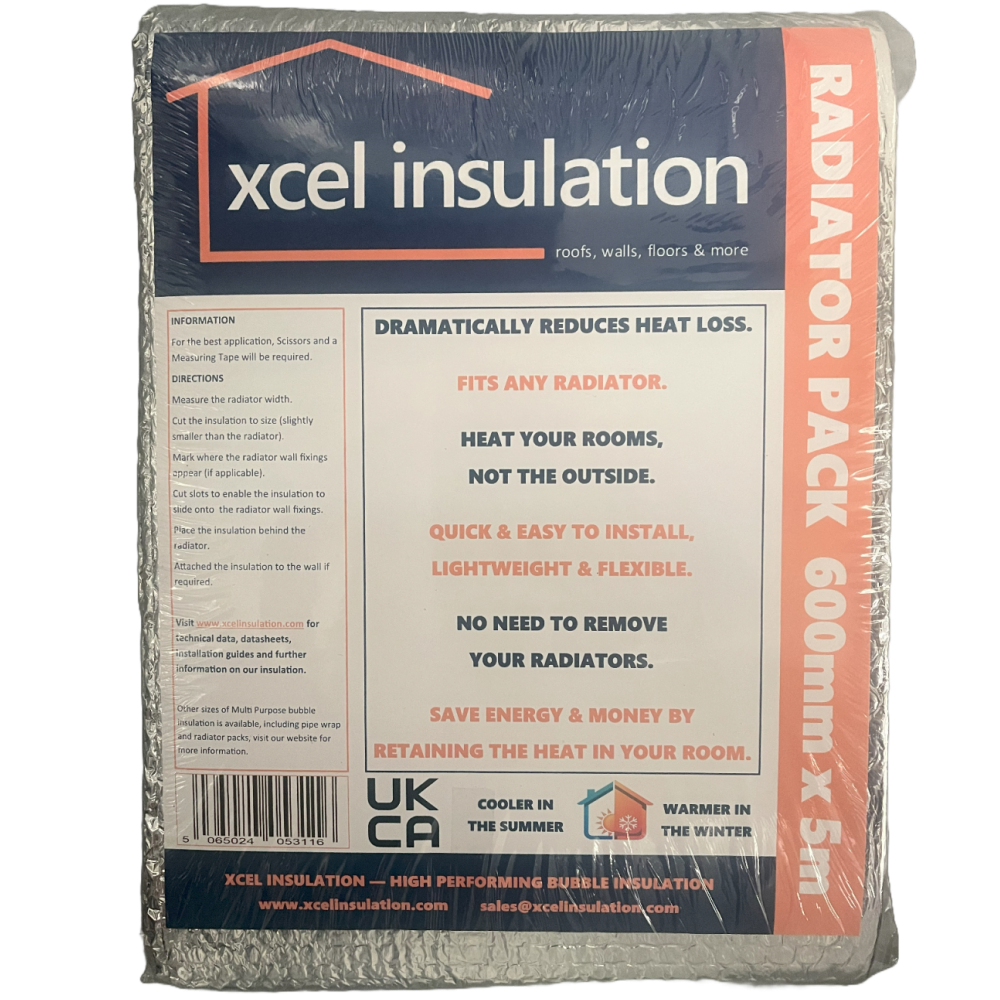

- Radiators (behind against the wall)

- Pipes - wrap to prevent freezing

- Packaging

- Cool Chain Logistics - Containers, Pallet Covers

- Windows - Reflect sun, keeping rooms cool

Insulation not only keeps rooms warmer in the winter, but also keeps rooms cooler in the summer.

The thermal reflective insulation manages heat effectively by reflecting heat away from the house in the summer keeping the house/room/building cool, whilst in winter, retaining the heat within the house from radiators and fireplaces, preventing heat loss.

FEATURES

All our bubble insulation products offer the similar key features that give the installer many advantages.

Thermal Efficient

R-Value equivalent to over 60mm of mineral wool. Multi Purpose insulation has a thickness of 3mm.

Save Time & Money

The insulation is thin, flexible and easy to install, saving time and money on each project.

Vapour Control

Built in airtight vapour control layer to prevent the passage of moisture, reducing the risk of condensation.

Multiple Benefits

The insulation not only keeps you warmer in Winter, but also cooler in the Summer.

Frequently Asked Questions

-

What is U value?

A U value, or overall heat transfer coefficient, quantifies heat loss in a building element like a wall, floor, or roof. It reflects the efficiency of heat transfer within different parts of a building. A higher U value implies poorer thermal performance in the building envelope, while a low U value typically suggests superior insulation. These values serve as a valuable means to predict how an entire building element behaves thermally, offering insight into the composite performance rather than relying solely on the properties of individual materials.

U values hold significance as they serve as the foundation for energy or carbon reduction standards. In practical terms, almost every external building component must adhere to thermal standards, typically defined by a maximum allowable U value.

-

What is Low- E?

Low emissivity (low-e or low thermal emissivity) pertains to a surface condition characterized by the emission of minimal levels of radiant thermal (heat) energy. While all materials inherently absorb, reflect, and emit radiant energy, the focus here is on a specific wavelength interval of radiant energy. -

What does emissivity mean?

Emissivity is the value given to materials based on the ratio of heat emitted compared to a blackbody, on a scale from zero to one. A blackbody would have an emissivity of 1 and a perfect reflector would have a value of Zero .

Materials with low emissivity values tend to reflect more infrared radiation and absorb less heat. -

What does reflectivity mean?

Reflectivity and emissivity are inversely related properties, and their sum for an opaque material equals 1. For instance, in the case of a low-emissivity (low-e) material like aluminum foil, it exhibits a thermal emissivity value of 0.03 and a thermal reflectance value of 0.97. This indicates that the material reflects 97 percent of radiant thermal energy and emits only 3 percent. Low-emissivity building materials encompass window glass with metal-oxide coatings, housewrap materials, reflective thermal insulations, and other types of radiant thermal barriers. -

What is R value?

The thermal resistance, often denoted by the letter "R," is a measure of a material's ability to resist the flow of heat. The higher the thermal resistance (R-value), the better the material is at impeding heat transfer. It is commonly used in the context of building insulation to evaluate how effectively a material or assembly resists heat flow.

The R-value is calculated by dividing the thickness of the material by its thermal conductivity.

In the context of building construction, a higher R-value is desirable, indicating better insulation and reduced heat transfer through walls, floors, roofs, or other building elements. It helps in assessing the overall thermal performance and energy efficiency of a structure. -

What is thermal conductivity (K value)?

Thermal conductivity is a material property that describes how well a substance conducts heat. It is a measure of the ability of a material to transfer heat through its mass. The higher the thermal conductivity, the more effective the material is at conducting heat. -

Does the R-value double when you install two layers of Reflective Insulation?

Improved performance is achieved with multiple layers of the product and airspaces between them. If the product is merely "doubled" without any airspace between the layers, the benefit is minimal. -

How do R-values for Reflective Insulation fluctuate across different applications, and what factors contribute to this variation?

Regarding R-values for Reflective Insulation and the reasons for their variation in different applications: Reflective insulation R-values depend on two primary criteria:

1. Heat flow direction.

2. The quantity of air space within a closed cavity on the reflective side of the product in a building assembly.

This variation in R-values for different applications is attributed to the differences in air space amounts and heat flow directions in each scenario. -

Why are air spaces required during installation?

To maximize the effectiveness of either reflective insulation or a radiant barrier, it is necessary to have a minimum thickness of air space on the reflective side. The benefits of reflective insulation stem from the interaction between the highly reflective surface and this air space. When the reflective surface is in direct contact with other building materials, it can conduct energy. An air space, specified on one or both sides (always on the reflective side), helps prevent this and is crucial for achieving the stated R-value, especially in enclosed spaces when instructed. -

Can Xcel Insulation be used with other insulation products or it be added to an existing insulation?

Yes! Xcel Insulation is a highly versatile product and can be used in combination with all other forms of insulation. By adding Xcel Insulation to an existing insulation, you are ensuring you have a high performance insulation which will save you money on your energy bills. -

I would like to order a large amount of insulation

Simply send us an email at sales@xcelinsulation.com and we can discuss your requirements direct for a great price.

Contact Us

Address:

Unit 21, Block B, Nobel Way, Dinnington, Sheffield, South Yorkshire, S25 3QB, UK

Email:

sales@xcelinsulation.com